The goal of this work package is the development and implementation of advanced casting processes, optimization of processing conditions and component manufacturing with increased mechanical properties for applications in structural vehicle components.

Aluminum mega structural castings are being touted by the industry as a likely alternative to complex welded steel assemblies, particularly for automotive suspension columns as well as other structural components. Using the HPDC process to produce mega castings will reduce weight and greatly simplify the design and assembly of the vehicles in the new BEV and FCEV class.

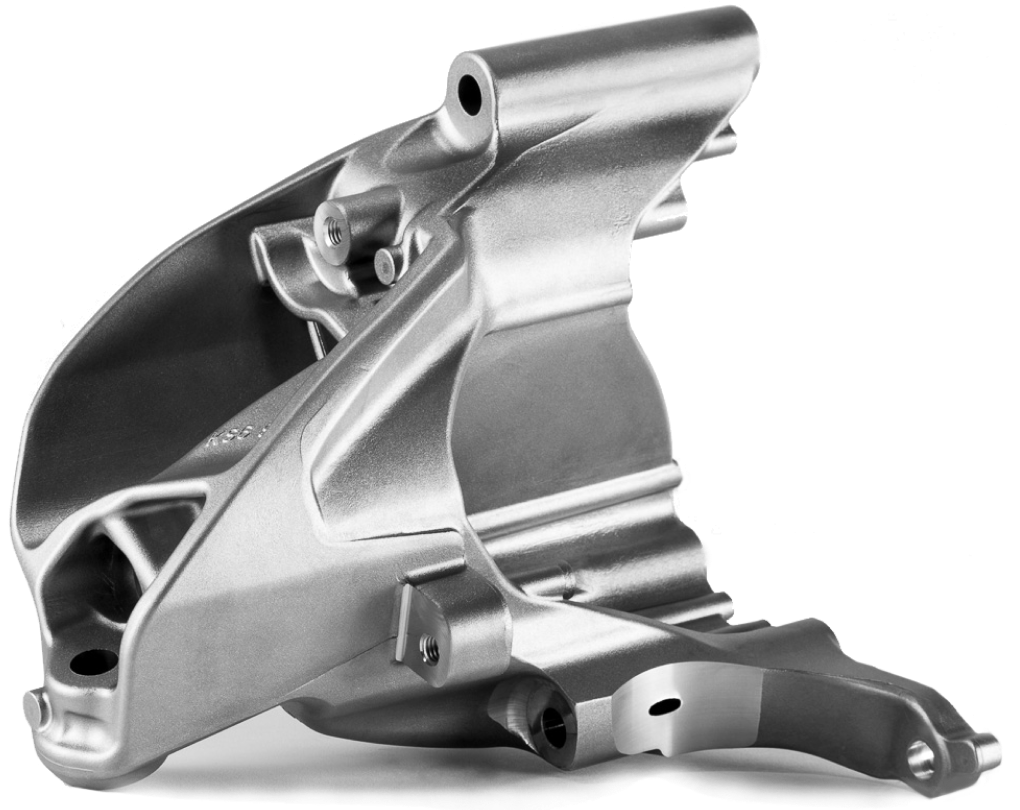

New high-performance and safety components for automotive suspension. New technologies and materials for the manufacture of new generations of suspension arms, steering knuckles, and other attachment components for new generation electric vehicles.

New lightweight steel products for car bodies, designed using topological optimization methodologies. These products include new grades of high-strength steels with high mechanical properties that allow a drastic reduction of the final BEV/FCEV weight through optimized design.